Coexisting in harmony with the environment

To protect the planet and pass it on to future generations,we are actively promoting sustainable manufacturing and

transitioning to electricity sourced from virtually 100% renewable energy.

Introducing Solar Power and Utilizing Green Energy

Achieving net-zero CO2 emissions from facility power consumption at Bandai Hobby Center

At the Bandai Hobby Center, the plastic model production plant operated by Bandai Spirits (Naganuma, Aoi-ku, Shizuoka-shi, Shizuoka Prefecture), we have effectively achieved net-zero CO2 emissions from power consumption through carbon offset initiatives and Power Purchase Agreements (PPA).

View more

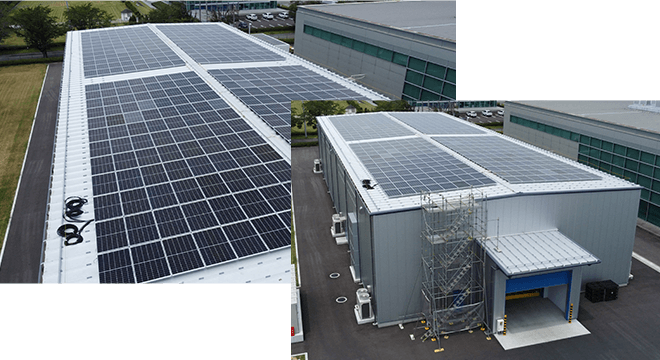

Solar panel installation at Bandai Namco Group production sites in Tochigi and Ehime

At two of our domestic production facilities, we've installed solar power systems through the PPA* model, aiming to reduce annual CO2 emissions by approximately 220 tons.

* Abbreviation for "Power Purchase Agreement." A business model in which the PPA provider leases spaces such as rooftops from consumers, installs solar power systems, and then sells the generated electricity back to the property owners.

-

Bandai Namco Craft (Tochigi) -

Heart Corporation (Ehime)

Switching to virtually renewable energy at our headquarters

At the Banda and Bandai Spirits headquarters buildings and five other locations, we've transitioned to using electricity with effectively zero CO2 emissions.

*Note: "Virtually renewable energy" refers to energy primarily sourced from non-fossil fuel options such as waste-to-energy plants. This approach utilizes non-fossil certificates to effectively reduce CO2 emissions to zero.

In this system, our waste recycling activities also contribute to achieving zero CO2 emissions for our company.

Our CO2 Reduction Declaration

Mirai and Creation Declaration

This declaration involves executives and employees committing to proactive measures to reduce CO2 emissions, and displaying their commitments around the company.

Throughout Bandai and Bandai Spirits, we've gathered over 1,000 declarations.

Designing products with the planet's future in mindImplementing sustainable design

When creating new products, we prioritize safety and enjoyment for all users by integrating environmental considerations and a deep understanding of diverse cultures.

To clearly communicate how sustainable practices are incorporated into our products, we mark those created with sustainability in mind with the "Sustainable Product Certification Mark" and provide detailed explanations.

Products that meet our environmental and sustainability criteria are labeled with the Sustainable Product Certification Mark.

Sustainable design focuses on reducing the environmental impact of products in all phases up to their disposal. This involves embedding eco-friendly practices based on the "Five Pillars of Sustainable Design" from the planning and design phases.

The "Five Pillars of Sustainable Design" and examples

Reducing plastic

We have substituted plastic packaging trays with cardboard to reduce plastic use.

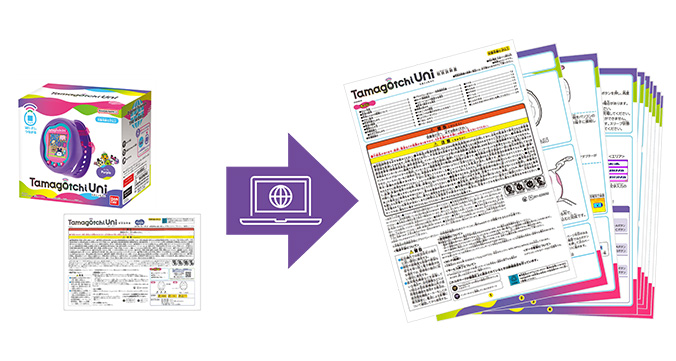

Reducing paper

By adopting online formats, we've significantly reduced the amount of paper used in manuals.

Changing materials

-

For wafer product series: We use biomass ink derived from natural resources such as cotton, pulp, rice bran, vegetable oil, and angiosperm seeds for the printing of packaging.

-

Left: S.H.Figuarts series (Bandai Spirits)

Right: Battle Spirits series (Bandai)The plastic trays we use for packaging are now made with innovative materials mixed with limestone or paper powder.

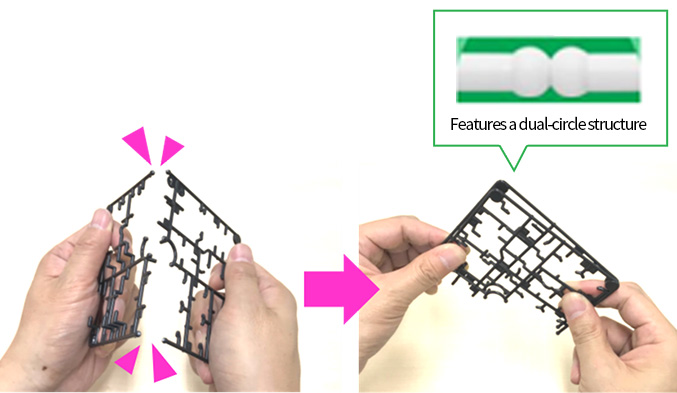

Easier disposal

-

Our packaging is designed to be robust during transport, yet easy to fold by hand to dispose of, effectively reducing waste volume.

-

This simplification of materials makes the products easier to sort and recycle.

Enhancing durability

We have increased the durability of our printed materials.

Transforming limited resourcesUtilizing recycled materials

ECOPLA

-

-

We recycle plastic model runners (the frames) collected from fans into raw materials for ECOPLA. (Bandai Spirits)

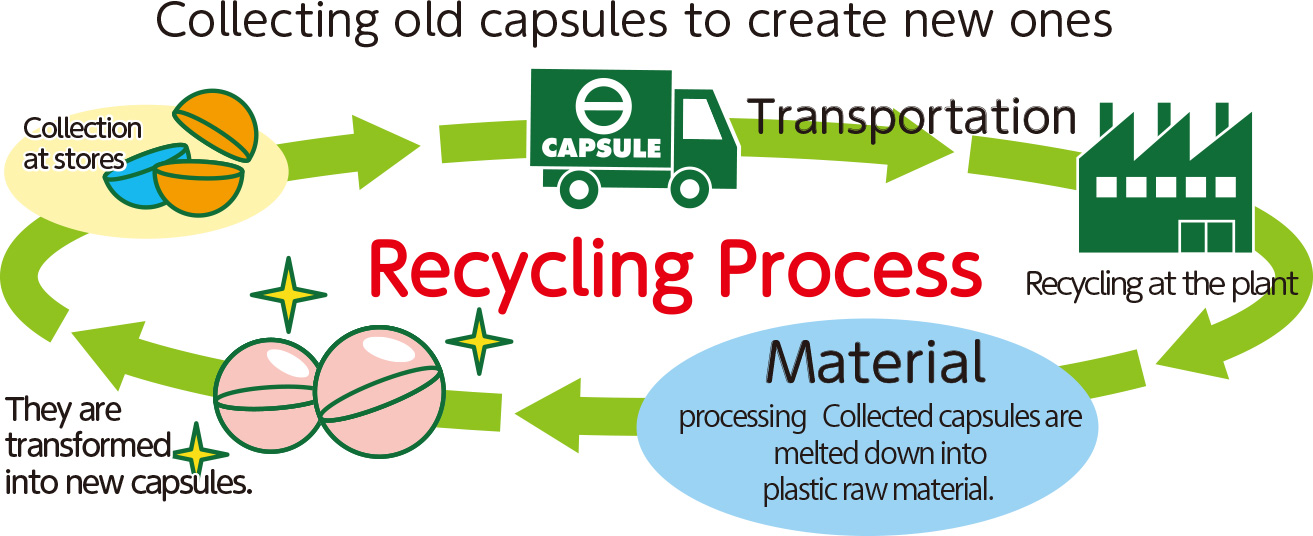

Capsule recycling project

We collect empty Gashapon capsules from locations such as our Gashapon Department Store, and then recycle them into plastic pellets at our facilities. These pellets are used to create new capsules at our Gashapon manufacturing plants. We reclaim over 30 tons* of capsules annually. (Bandai)

* Equivalent to 6 million capsules of 5 cm in diameter.

View more

Reducing plastic usagesAdopting plastic alternatives

Used Japanese tea leaves, eggshell, LIMEX

-

We are incorporating plastic alternative materials into some of our plastic models.

Through these efforts, we aim to reduce the use of petroleum-based plastics and contribute to the reduction of CO2 emissions. (Bandai Spirits)

Discovering New Possibilities for PlasticPractical Application of Plastic Models Using Chemically Recycled Resin

By chemically breaking down used Gundam model runners and returning them to chemical raw materials for reuse, we have implemented "chemical recycling," making it possible to produce high-quality recycled plastic equivalent to new materials.

Reducing food wasteEfforts to minimize food loss

-

Reducing food loss with the Tsuri-Gummy Series and Charapaki Hakkutsu Kyoru Choco As part of our response to the societal issue of food loss, we have conducted numerous experiments over five years on our main sweets products, including Tsuri-Gummies, Tray Gummy Series, Ramune, and desserts. This research has enabled us to extend the shelf life of these products. Additionally, we have made efforts to reduce waste in raw materials and finished products during the production process and to extend sell-by periods, thereby reducing food loss. (Bandai)

Craftsmanship that meets the expectations of fansEnhancing and passing down techniques

-

At the Bandai Hobby Center, we strive to improve and pass on plastic model production techniques in order to meet the expectations of our fans and continue to improve the value of plastic models. (Bandai Spirits)

Bandai Hobby Center

Main building (Right) and new building (Left) of the Bandai Hobby Center*The solar panels on the wall of the main building were installed in 2006.

At the Bandai Hobby Center (Naganuma, Aoi-ku, Shizuoka-shi, Shizuoka), which serves as the plastic model production plant for Bandai Spirits, carbon offsetting and power purchase agreements (PPAs) have reduced CO2 emissions from electricity use to net zero.

Through the carbon offset initiative, which was introduced in July 2022, we purchase electricity from renewable energy sources with non-fossil certificates with tracking information (*1). As a result, the Bandai Hobby Center uses electricity with net zero CO2 emissions.

As part of our efforts to achieve self-sufficiency in electric power through the photovoltaic power generation PPA business, we installed solar panels across approximately 1,202 m2 of the rooftop area of the Bandai Hobby Center, and we plan to use the photovoltaic power we generate starting in April 2023. The annual amount of electricity supplied from our own rooftop solar panels is planned to be approximately 260,000 kWh (*2).

Since the completion of the Bandai Hobby Center in 2006, we have installed 324 solar panels on the walls of the main building, and we have been working to reduce the environmental impact of the facility by using electricity generated from sunlight. Through these efforts, the Bandai Hobby Center will continue to contribute to the reduction of CO2 emissions.

(*1) Non-fossil certificates with tracking information are certificates of environmental value associated with electricity generated from solar, wind, biomass, geothermal, and small hydroelectric generation methods and the location of the power plants. Environmental value refers to zero-emissions value (zero CO2 value), non-fossil value (value under the Sophisticated Methods of Energy Supply Structures), and environmental labeling value (clearly labeled added value).

(*2) Calculated using a method to deduce the amount of electricity generated by solar cells according to JIS 8907.